At Incite Novelty, our Engineering Design Services bridge the gap between concept and manufacturable reality. Leveraging decades of experience and industry-best practices, we provide precision-driven design solutions tailored for mechanical components, assemblies, and systems. From initial concept evaluation to detailed CAD modelling and design validation, our focus is on quality, manufacturability, and performance — ensuring your product is production-ready at every step.

We start by understanding your product goals and functional requirements. Our team evaluates feasibility, material selection, and possible design alternatives to ensure optimal engineering decisions from the outset.

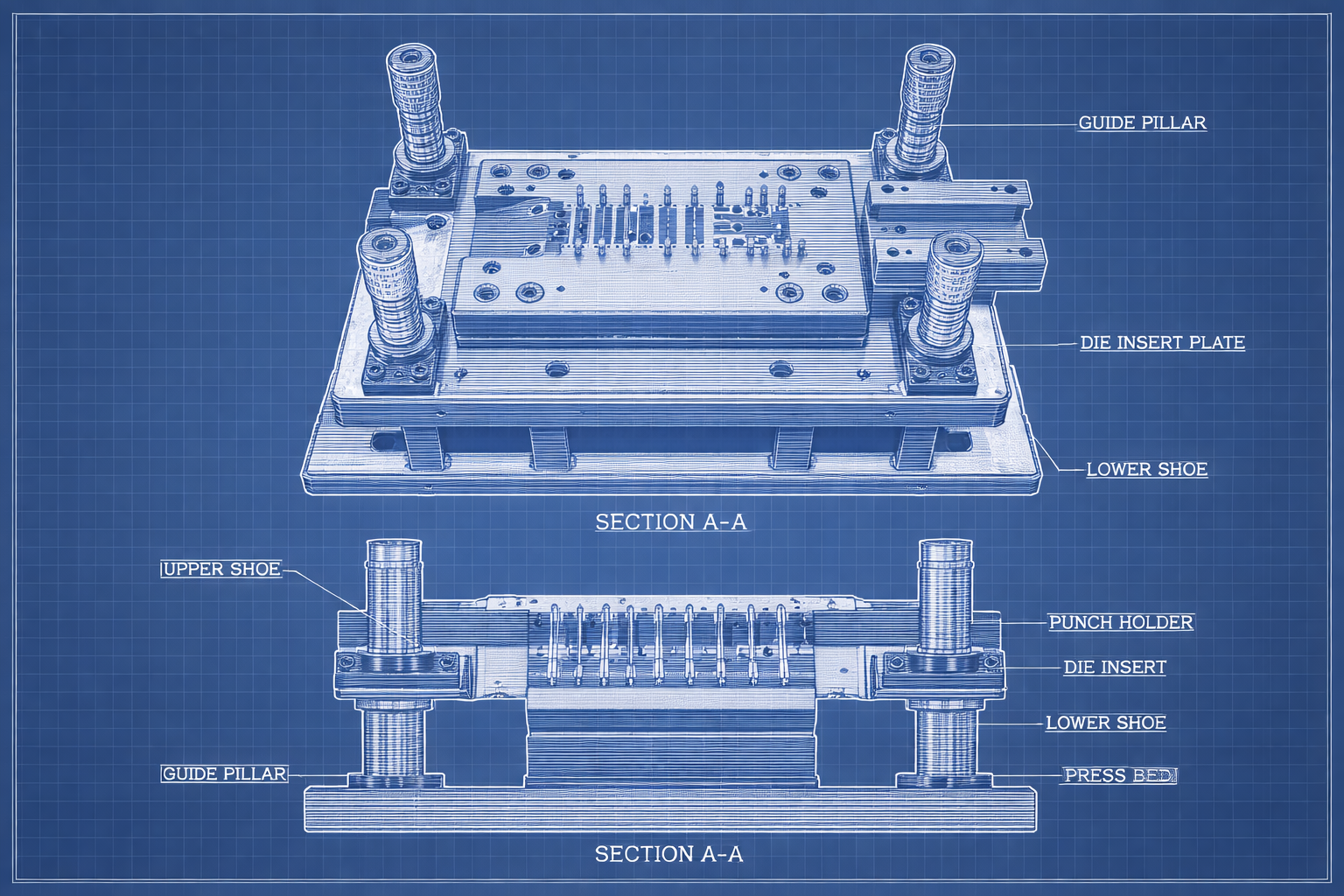

Using advanced CAD platforms, we create accurate 3D models and detailed 2D drawings that conform to industry standards, enabling seamless downstream processes like toolmaking, simulation, and production planning.

Precision is critical — especially for assemblies that require tight tolerances. We perform tolerance stack analysis and refine fits to achieve functionally reliable components without unnecessary manufacturing costs.

Our designs are optimized for manufacturability and assembly. By incorporating Design for Manufacturing (DFM) and Design for Assembly (DFA) principles, we reduce production cycle times and eliminate costly revisions.

Before production, we validate designs for strength, motion, interference, and assembly performance — ensuring every part functions exactly as intended.

Engineering design lays the foundation for successful products. A well-engineered design:

Reduces production risk and rework

Lowers costs by eliminating inefficiencies

Improves product reliability and performance

Shortens time-to-market through faster transitions to tooling and manufacturing

Requirement Gathering: We begin with detailed discussions to fully capture technical specifications, usage conditions, constraints, and expectations.

Preliminary Concept Design: Multiple design directions are explored and evaluated.

CAD Development: Preferred concept is developed into a detailed 3D model with accurate geometry and material definitions.

Engineering Review & Iterations: Through collaborative reviews, designs are refined to ensure compliance with all functional and production needs.

Final Design Delivery: Complete CAD files, drawings, and documentation are delivered, ready for tooling and manufacturing.

Automotive & Heavy Engineering

Industrial Machinery & Equipment

Consumer Products & Appliance Components

Medical Devices & Precision Assemblies

Energy & Power Systems

Experienced Engineering Team: Skilled professionals with deep domain knowledge and practical understanding.

Advanced Tools & Technologies: Up-to-date CAD software and simulation tools for precision work.

Seamless Collaboration: We work closely with your team to ensure design intent is fully aligned.

ISO-Aligned Quality Standards: Rigorous checks throughout the design lifecycle to maintain quality and compliance.

Whether you are developing a new product or optimizing an existing design, our engineering design services help you achieve measurable improvements in performance and producibility.

➡ Contact us today to discuss your project and accelerate your product journey.